torsion test in the plastic range|plastic torsion tests : makers In this work, prismatic bars of circular cross sections have been loaded in torsion to study their responses in elastic and elastic-plastic . See more Resultado da KİMDİR. FOTOĞRAFLARI. Sinema ve dizi film oyuncusu. 2002, İzmir doğumlu. İzmir Ekonomi Üniversitesi Sinema ve Dijital Medya Bölümü mezunudur. Eylül Tumbar, 2023 yılından itibaren Biz Kimden Kaçıyorduk Anne?, Kendi Düşen Ağlamaz gibi çeşitli dizilerde rol aldı. Yeni projelerde .

{plog:ftitle_list}

8 de ago. de 2019 · Bazzi - Live Forever [Official Audio] Bazzi. 3.23M subscribers. Subscribe. Subscribed. 13K. 653K views 4 years ago #LiveForever #Bazzi #SoulSearching.

shear stress test torsion

special tests for labral tear

plastic torsion tests

In this work, prismatic bars of circular cross sections have been loaded in torsion to study their responses in elastic and elastic-plastic . See moreThis project introduces the students to material plasticity through torsion experiment involving loads that causes the material to yield. As the torque is increased, a plastic . See moreAn extension of the membrane analogy to elastic/plastic torsion has also been suggested by (Nadai, 1950). It is necessary to erect a . See more

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .The total torque is a function of the torque in the elastic range and the torque in the plastic range.If a certain object is subjected to uniaxial tensile load, it will start yielding – deforming plastically – when the stress reaches the uniaxial yield stress Y. However, when the state of stress is .

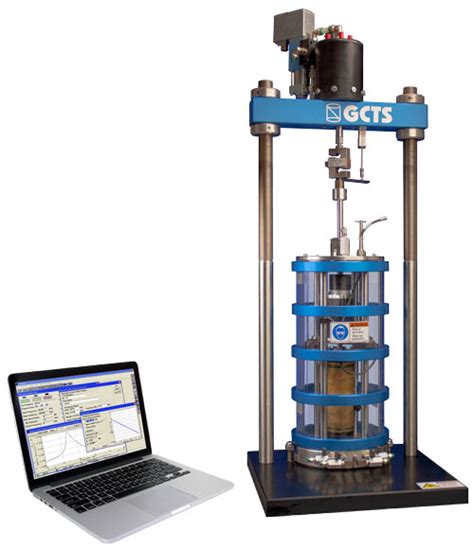

The physical testing of plastic materials for the purpose of designing material constitutive models in finite element analysis can be very simple or incredibly complex depending on the objective .Torsion Testing of Structural Metals Standards • ASTM E143: Shear Modulus at Room Temperature Purpose • To determine the shear modulus of structural metals Equipment • .

squat test for meniscus tear

The proposed plastic torsional analysis allows a method of plastic design to be used for torsion that is much simpler and more economical than first yield design. The use of plastic analysis . In research and industry, the in-plane torsion test is applied to investigate the material behaviour at large plastic strains: a sheet is clamped in two concentric circles, the . A shear stress–strain diagram determined from torsion test is fundamentally more important in characterizing the plastic behaviour of material than a conventional or a true . Torsion tests provide important shear stress and shear strain relationships to reveal the fundamental plastic flow response of a material.

Semantic Scholar extracted view of "Torsion test of aluminum in the large strain range" by Han-chin Wu et al. . The determination of large strain isotropic hardening elasto-plastic constitutive model was studied by . isotropic hardening rate-type elastoplastic constitutive model with the logarithmic stress rate utilizing solid shafts .Torsion test machine with grips, troptometer, and load sensor. PROCEDURE. Measure the diameter (D=2R) of the gage section for each specimen to 0.02 mm. . The total torque is a function of the torque in the elastic range and the .well as tension, hardness, torsion, and impact tests in particular. Mechanical Testing Mechanical tests (as opposed to physical, electrical, or other types of tests) often involves the deformation or breakage of samples of material (called test specimens or test pieces). Some common forms of test specimens and loading situations are shown in .

• Wide range of test specimens • Optional Torsiometer (SM1001a) available for tests which need increased accuracy Screenshot of the optional VDAS® software Torsion Testing Machine (30 Nm) SM1001 Benchtop machine to allow students to do torsion tests on diff erent materials. Demonstrates Bauschinger eff ect. Materials Testing and Properties

ME 354 LAB #4: DISCUSSION OF THE TORSION TEST Each lab section performed a torsion test of a cylindrical 6061-T6 aluminum specimen. The specimen was mounted in a Technovate model 9041 Torsion Tester. A top view is shown in . The plastic region extends over ry .

In particular, the results from the torsion test will be compared to the results of the engineering tensile test for a particular alloy using the effective stress-effective strain concept. EQUIPMENT • Constant-diameter gage section torsion specimen of 6061-T6 aluminum • Torsion test machine with grips, troptometer, and force sensor. PROCEDURE

Materials testing machines with torsion drive enable fast, precise biaxial testing (tensile or compression combined with torsion) of materials or components up to 10,000 Nm. In addition to tests on artificial ball-and-socket joints and bone-replacement material, torsion tests are also performed on items such as clutch plates, steering shafts .

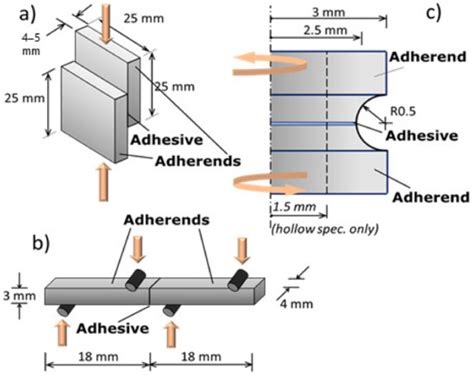

Torsion Testing Equipment. Torsion testing can be performed on any one of several different testing systems depending on the specific application. Some labs prefer a dedicated torsion-only testing system such as Instron's MT MicroTorsion Series, while others may prefer to adapt their existing universal testing machine with a Torsion Add-On 3.0 fixture that enables the system .6. Set speed to ~ 5°/min, zero the torque and start test (figure 1.2.4). Figure 1.2.4. Torsion controls. Structural Metals Lab 1.2 53:086 – Spring 2008 The University of Iowa 11 7. When the specimen reaches the plastic range (permanent deformation), stop the machine. Notice the line is now twisted. Remove the specimen. 8. Obtain the data .ASTM D5868 bonding test for lap shear adhesion plastic is intended to meet the inc. FTM 3 Low Speed Release Force. . Choose from a wide range of torsion capacities with 7 frame styles and 100's of configurations which allows you to optimize your testing capabilities and pick exactly what you need. Our extensive product line of torsion test . In determining the flow curve, Torsion test is used in determining strains where the strains of higher ranges (i.e., greater than 1) are achieved when compared to the uniaxial tension or .

In a torsion test, the plastic deformation of the cylinder is consistent along its entire length, and the section and gauge length of the test piece remain constant without any necking phenomenon during static tension. . Torsion speed: The speed must range from 3° to 30° per minute before yielding, and must not exceed 720° per minute after .

Strain corresponding to specified torque in torsion test. It is equal to torsional deformation multiplied by the radius of the shaft. It's units are radians. 14. Torsional Stress, T: Shear stress developed in a material subjected to a specified torque in torsion test for a circular shaft. It can be calculated using the expression. 15.The Shear Stress-Strain Curve Determination from Torsion Test in the Large Strain Range HC Wu, HC Wu 1. Professor and graduate student, respectively, Department of Civil Engineering, The University of Iowa, . Anisotropy in Plastic Torsion,” Journal of Basic Engineering 0021-9223, Vol. 94, 1972, pp. 231-One of the most common examples of torsion in engineering design is the power generated by transmission shafts. We can quickly understand how twist generates power just by doing a simple dimensional analysis.Power is measured in the unit of Watts [W], and 1 W = 1 N m s-1.At the outset of this section, we noted that torque was a twisting couple, which means that it has .

The Shear Stress Determination in Tubular Specimens under Torsion in the Elastic-Plastic Strain Range from the Perspective of Fatigue Analysis December 2020 Materials 13(5583)the torsion test specimen will be twisted to failure in order to determine the shear stress at the limit of proportionality. The shear stress at the limit of proportionality is the largest value of the shear stress for which the material will behave elastically. Throughout this discussion the plot of

Our product, plastic and rubber testing laboratories are equipped to conduct axial, torsional, or combined axial-torsion tests.

Torsion test results and first-yield and full-plastic yield torque estimates for 5050-H32 rectangular specimens. (a) 50-R-AR1; (b) 50-R-AR2; (c) 50-R-AR3; (d) 50-R-AR4. The torques associated with initial-yield as determined using the median 0.2% yield strength from the associated tension tests, T y tt , occur at an ordinate location where the .

It was found that the long, thick-walled tubular specimen is suitable for torsion test in the large strain range. . In the free-end torsion test, the solid shaft leads to low length change compared to a tubular specimen. . Anisotropy in plastic torsion. Journal of Basic Engineering (1972) Billington, E. W. (1977) Non-linear mechanical .

Torsion Testing Systems. With an ADMET material testing system, you can accurately and reliably measure the torsional properties of metals, plastics, textiles, adhesives, medical devices and many other products and components. Capacities of the Torsion Load Frames range from 5Nm to 300Nm. Torque capacity load cells range from 0.1Nm to 200Nm.A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, . Keywords: cyclic torsion; shear stress; tubular specimens; elastic–plastic torsion 1. Introduction Usually, fatigue cracks originate on a free surface due to the stress concentration on a micro and macro scale. Given polycrystalline materials, plastic deformation is also higher on a surface as a result of lower constraints from neighboring .

One principal discussion is about the stress and strain state, since the in-plane torsion test achieves equivalent plastic strains above 3.0 (Traphöner et al . provides less accurate results in the small strain range. Since both the tensile test and the plane strain compression test are performed so that the main metal flow direction is in .Intertek provides safety and performance certification to nationally recognized standards for a wide range of products. Our product directories allow you to easily verify products that carry our marks. . ASTM polymer and plastic test techniques: ABC: Ash Content ASTM D5630, D2584, ISO 3451 . Dynamic Mechanical Analysis (DMA) - Torsion ASTM .An example for a torsion hydraulic actuator test (Figure 2.1) for the medium velocity range is given by Lindholm and Johnson [2], cited in the ASM Handbook vol. 8 by Lindholm et al. [3], with the determination of shear-stress–shear-strain curves of different materials.The failure strain and the strain-hardening coefficient are taken. The specimen used was a tube form with an outer .of the five experiments in the laboratory c ourse focuses on the study of elastic and plastic deformation of a circular cross-s ection metallic rod in torsion. The objectives of the torsion experiment include determination of shear modulus of elasticity G and shear proportional limit Wp of the material. In the torsi on test, a torque T is applied

webWin2023 é o site de jogos de cassino online que oferece os melhores jogos de slots, .

torsion test in the plastic range|plastic torsion tests